Scan the QR code

Multi-core design: the common ones are 2-core, 3-core, 4-core, etc.

The conductor insulation material of KVVR cables usually uses PVC

Flexibility: KVVR cable has high flexibility and bending performance, is easy to install and route, and is suitable for occasions that require frequent movement or bending.

Anti-interference ability: Some KVVR cables may have a shielding layer to reduce the impact of external electromagnetic interference on the signal

Introduction

KVVR is a specific type of control cable commonly used in industrial automation, instrumentation and control systems. KVVR cable is a multi-core flexible cable, where "KV" represents polyvinyl chloride (PVC) insulation material, "V" represents polyvinyl chloride (PVC) sheath material, and "R" represents softness.

Application

KVVR cables are widely used in industrial automation, instrumentation and control systems and other fields. Here are some common KVVR cable application scenarios:

Control system: It can be used to connect and transmit control signals, such as signal transmission between PLC (programmable logic controller), DCS (distributed control system) and other control devices.

Instruments and sensors: Can be used to connect various instruments and sensors, including temperature sensors, pressure sensors, flow sensors, etc., in order to transmit instrument signals or monitor the status of equipment.

Robots and automation equipment: It can be used to connect robots, automation equipment and control units to achieve control, monitoring and data transmission of robots and equipment.

Industrial communication network: KVVR cable can be used as a connecting cable in industrial Ethernet, Modbus,Profibus and other communication networks to realize data communication and information exchange between devices.

Industrial communication network: KVVR cable can be used as a connecting cable in industrial Ethernet, Modbus, Profibus and other communication networks to realize data communication and information exchange between devices.

Power wiring: can be used for low-voltage power wiring, such as electrical wiring and electrical equipment connections inside buildings

Specification

lPYC, XLPE Insulation/ Unshield/ Unarmoured/ PVC, PE and LOSH sheath

lPYC, XLPE Insulation/ Copper tape shield/ Unarmoured/ PVC, PE and LOSH sheath

lPVC, XLPE Insulation/Braiding shield/ Unarmoured/ PVC, PE and LOSH sheath

lPVC, XLPE Insulation/ Unshield/ Galvanized steel tape armoured/ PVC, PE and LOSH sheath

lPVC, XLPE Insulation/ Copper tape shield/ Galvanized steel tape armoured/ PVC, PE and LOSH sheath

lPVC, XLPE Insulation/ Unshield/ Galvanized steel wire armoured/ PVC, PE and LOSH sheath

lPVC, XLPE Insulation/ Copper tape shield/ Galvanized steel wire armoured/ PYC, PE and LOSH sheath

| Type | Name | Sectional Area(mm²) | Number of Cores | Application |

| KVV | Copper Corse, PVC Insulated, PVC SheathedControl Cable | 0.75, 1.0, 1.5, 2.5 | 2~16 | Permanent installation indoors, in cable ditches or pipes |

| 4, 6 | 2~14 | |||

| 10 | 2~10 | |||

| KVVP | Copper Cores, PVC Insulated, PVC,Sheathed and,Braided Screen,Control Cable | 0.75, 1.0, 1.5, 2.5 | 2~61 | Permanent installation indoors, in cable ditches or pipes where shielding is required |

| 4, 6 | 2~14 | |||

| 10 | 2~10 | |||

| KVVP2 | Copper Cores, PVC Insulated, PVC Sheathed, Copper TapeScreened Control Cable | 0.75, 1.0, 1.5, 2.5 | 4~10 | Permanent installation indoors, in cable ditches or pipes where shielding is required |

| 4, 6 | 7~61 | |||

| 10 | 4~10 | |||

| KVV22 | Copper Conductor, PVC Insulated and Sheathed, Steel-tape Armoured Control Cable | 0.75, 1.0, 1.5, 2.5 | 7~61 | Permanent installation indoors, in cable ditches, pipes or underground, be able to bear stronger external mechanical force |

| 4, 6 | 4~14 | |||

| 10 | 4~14 | |||

| KVVR | Copper Conductor, PVC Insulated and Sheathed Flexible Control Cable | 0.5~2.5 | 4~61 | Installation indoors where flexibility, and mobility are required |

| KVVRP | Copper Cores, PVC Insulated, PVC Sheathed and Braided ScreenFlexible Control Cable | 0.75, 1.0, 1.5, 2.5 | 4~61 | Installation indoors where flexibility, shielding and mobility are required |

| 1.5, 2.5 | 4~48 | |||

| KYJV | Copper Cores, XLPE Insulated, PVC Sheathed,Control Cable | 0.75, 1.0, 1.5, 2.5 | 2~16 | Permanent installation indoors, in cable ditches or pipes |

| 4, 6 | 2~14 | |||

| KYJV | Copper Cores, XLPE Insulated, PVC Sheathed,Control Cable | 10 | 2~10 | Permanent installation indoors, in cable ditches or pipes |

| KYJVP | Copper Cores, XLPE Insulated, PVC Sheathed and Braided Screen Control | 0.75, 1.0, 1.5, 2.5 | 2~61 | Permanent installation indoors, in cable ditches or pipes where shielding is required |

| 4, 6 | 2~14 | |||

| 10 | 2~10 | |||

| KYJV22 | Copper Cores, XLPE Insulated, Steel-taped Armoured, PVC Sheathed Control Cable | 0.75, 1.0, 1.5, 2.5 | 7~61 | Permanent installation indoors, in cable ditches, pipes or underground.Be able to bear stronger outer mechanical force |

| 4, 6 | 4~14 | |||

| 10 | 4~10 | |||

| KYJVP2 | Copper Cores, XLPE Insulated, PVC Sheathed and Copper Taped ScreenedControl Cable | 0.75, 1.0, 1.5, 2.5 | 7~61 | Permanent installation indoors, in cable ditches or pipes where shielding is required |

| 4, 6 | 4~14 | |||

| 10 | 4~10 | |||

| KYJVR | Copper Cores, XLPE Insulated, PVC Sheathed, Flexible Control Cable | 0.5~2.5 | 4~61 | Installation indoors where flexibility and movability are required |

| KYJVRP | Copper Cores, XLPE Insulated, PVC Sheathed, and Braided ScreenFlexible Control Cable | 0.5, 0.75, 1.0 | 4~61 | Installation indoors where flexiblility, shielding and movability are required |

| 1.5, 2.5 | 4~48 |

KVVR Parameter

Type KVV,ZR-KVV 450V/750V Copper Conductor PVc insulated and Sheath Control Cables | |||||||

Crossx Nom cross sectional area mm2 | Nom thickness ofInsulation mm | Nom thickness ofSheath mm | Pitch Diameter mm | Max.D.C Resistance of Insulation at 20°C (Ω/km) | Max.D.C Resistance at 20℃ (Ω/km) | Approx weight(kg/km) (9/km) | |

min | max | ||||||

2x0.75 | 0.6 | 1.2 | 6.4 | 8.0 | 0.012 | 24.5 | 59 |

2x1 | 0.6 | 1.2 | 6.8 | 8.4 | 0.011 | 18.1 | 67 |

2x1.5 | 0.7 | 1.2 | 7.6 | 9.4 | 0.011 | 12.1 | 86 |

2x2.5 | 0.8 | 1 2 | 8.6 | 10.5 | 0.010 | 7.41 | 120 |

2x4 | 0.8 | 1.2 | 9.6 | 11.5 | 0.0085 | 4.61 | 167 |

2x6 | 0.8 | 1 .2 | 10.5 | 12.5 | 0.0070 | 3.08 | 220 |

3x0.75 | 0.6 | 1.2 | 6.8 | 8.4 | 0.012 | 24.5 | 71 |

3x] | 0.6 | 1.2 | 7.0 | 8.8 | 0.011 | 18 1 | 82 |

3x1.5 | 0.7 | 1.2 | 8.0 | 9.8 | 0.017 | 12.1 | 108 |

3x2.5 | 0.8 | 1.2 | 9.2 | 11.0 | 0.010 | 7.41 | 154 |

3x4 | 0.8 | 7.2 | 10.0 | 125 | 0.0085 | 4.6] | 210 |

3x6 | 0.6 | 1.5 | 11.5 | 14.0 | 0.0070 | 3.08 | 310 |

4x0.75 | 0.6 | 1.2 | 7.2 | 9.0 | 0.012 | 24.5 | 846 |

4x1 | 0.7 | 7.2 | 7.6 | 9.4 | 0.011 | 18.1 | 100 |

4x1.5 | 0.8 | 1.2 | 8.6 | 10.5 | 0.011 | 12.7 | 732 |

4x2.5 | 0.8 | 1.2 | 10.0 | 12.0 | 0.010 | 7.41 | 193 |

4x4 | 0.8 | 1.5 | 11.5 | 14.0 | 0.0085 | 4.61 | 315 |

4x6 | 0.8 | 1.5 | 12.5 | 15.0 | 0.0070 | 3.08 | 413 |

5x0.75 | 0.6 | 1.2 | 7.8 | 9.6 | 0.012 | 24.5 | 99 |

5x1 | 0.6 | 1.2 | 8.2 | 10.0 | 0.011 | 18.7 | 116 |

5x1.5 | 0.7 | 1.2 | 9.4 | 11.5 | 0.011 | 12.1 | 154 |

5x25 | 0 8 | 1.5 | 11.5 | 14.0 | 0.010 | 7.41 | 243 |

5x4 | 0.8 | 1.5 | 72.5 | 15.0 | 0.0085 | 4.61 | 383 |

5x6 | 0.8 | 1.5 | 14.0 | 16.5 | 0.0070 | 3.08 | 505 |

7x0.75 | 0.6 | 1.2 | 8.4 | 10.5 | 0.012 | 24.5 | 123 |

7x1 | 0.6 | 1.2 | 9.0 | 11.0 | 0.011 | 18 7 | 146 |

7x1.5 | 0.7 | 1.2 | 10.0 | 12.5 | 0.011 | 12.1 | 196 |

7x2.5 | 0.8 | 1.5 | 12 5 | 15.0 | 0.010 | 7.41 | 211 |

7x4 | 0.8 | 7.5 | 13.5 | 16.5 | 0.0085 | 4.61 | 473 |

7x6 | 0.8 | 1.5 | 15.0 | 18.0 | 0.0070 | 3.08 | 652 |

Component composition

Packaging: wooden barrel

Goods: finished product + wooden barrel packaging

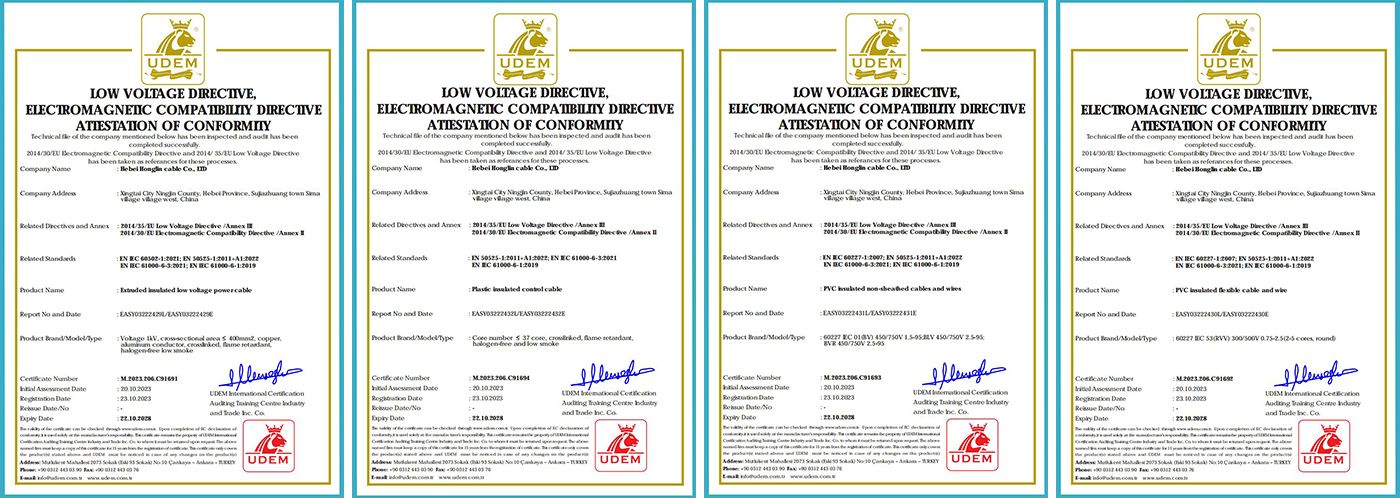

Certification

Manufacturing process

There are nine steps in the low-voltage power cable production process:stranding machine; extrud; cooling; diameter measurement; Bearing winch; Set meter counter; testing; Spark test; packing

Payment Method

T/T; L/C ; Western Union