Scan the QR code

Versatility and Compatibility: Widely used, suitable for all kinds of electrical appliances. Compatible with a wide range of electrical accessories, ensuring the cord can be easily integrated into different electrical systems and components.

KVV wire's multiple conductors are contained within a single sheath, saving space.

Flexible, easy to handle and install.

Easy to identify: KVV wires usually have color-coded insulation on each conductor, making it easy to identify and differentiate between different signal or power wires.

Introduction

KVV is the abbreviation of "Copper Core PVC Insulated PVC Sheathed Control Cable" (Copper Core PVC Insulated PVC Sheathed Control Cable)."

KVV is a common type of wire and cable commonly used for electrical wiring in buildings.

KVV wire and cable are multi-core cables, usually composed of 2 or more copper core conductors. Each conductor is insulated with PVC insulation material.

All conductors are surrounded and protected by an integral PVC jacket. The PVC jacket provides additional protection against mechanical damage and the effects of the external environment on the cable.

Application

KVV wires and cables are often used in control loops in electrical systems for indoor fixed installations. It is suitable for control and signal transmission applications, such as control systems for electrical equipment, automation equipment, and instrumentation.

Specification

lPYC, XLPE Insulation/ Unshield/ Unarmoured/ PVC, PE and LOSH sheath

lPYC, XLPE Insulation/ Copper tape shield/ Unarmoured/ PVC, PE and LOSH sheath

lPVC, XLPE Insulation/Braiding shield/ Unarmoured/ PVC, PE and LOSH sheath

lPVC, XLPE Insulation/ Unshield/ Galvanized steel tape armoured/ PVC, PE and LOSH sheath

lPVC, XLPE Insulation/ Copper tape shield/ Galvanized steel tape armoured/ PVC, PE and LOSH sheath

lPVC, XLPE Insulation/ Unshield/ Galvanized steel wire armoured/ PVC, PE and LOSH sheath

lPVC, XLPE Insulation/ Copper tape shield/ Galvanized steel wire armoured/ PYC, PE and LOSH sheath

| Type | Name | Sectional Area(mm²) | Number of Cores | Application |

| KVV | Copper Corse, PVC Insulated, PVC SheathedControl Cable | 0.75, 1.0, 1.5, 2.5 | 2~16 | Permanent installation indoors, in cable ditches or pipes |

| 4, 6 | 2~14 | |||

| 10 | 2~10 | |||

| KVVP | Copper Cores, PVC Insulated, PVC,Sheathed and,Braided Screen,Control Cable | 0.75, 1.0, 1.5, 2.5 | 2~61 | Permanent installation indoors, in cable ditches or pipes where shielding is required |

| 4, 6 | 2~14 | |||

| 10 | 2~10 | |||

| KVVP2 | Copper Cores, PVC Insulated, PVC Sheathed, Copper TapeScreened Control Cable | 0.75, 1.0, 1.5, 2.5 | 4~10 | Permanent installation indoors, in cable ditches or pipes where shielding is required |

| 4, 6 | 7~61 | |||

| 10 | 4~10 | |||

| KVV22 | Copper Conductor, PVC Insulated and Sheathed, Steel-tape Armoured Control Cable | 0.75, 1.0, 1.5, 2.5 | 7~61 | Permanent installation indoors, in cable ditches, pipes or underground, be able to bear stronger external mechanical force |

| 4, 6 | 4~14 | |||

| 10 | 4~14 | |||

| KVVR | Copper Conductor, PVC Insulated and Sheathed Flexible Control Cable | 0.5~2.5 | 4~61 | Installation indoors where flexibility, and mobility are required |

| KVVRP | Copper Cores, PVC Insulated, PVC Sheathed and Braided ScreenFlexible Control Cable | 0.75, 1.0, 1.5, 2.5 | 4~61 | Installation indoors where flexibility, shielding and mobility are required |

| 1.5, 2.5 | 4~48 | |||

| KYJV | Copper Cores, XLPE Insulated, PVC Sheathed,Control Cable | 0.75, 1.0, 1.5, 2.5 | 2~16 | Permanent installation indoors, in cable ditches or pipes |

| 4, 6 | 2~14 | |||

| KYJV | Copper Cores, XLPE Insulated, PVC Sheathed,Control Cable | 10 | 2~10 | Permanent installation indoors, in cable ditches or pipes |

| KYJVP | Copper Cores, XLPE Insulated, PVC Sheathed and Braided Screen Control | 0.75, 1.0, 1.5, 2.5 | 2~61 | Permanent installation indoors, in cable ditches or pipes where shielding is required |

| 4, 6 | 2~14 | |||

| 10 | 2~10 | |||

| KYJV22 | Copper Cores, XLPE Insulated, Steel-taped Armoured, PVC Sheathed Control Cable | 0.75, 1.0, 1.5, 2.5 | 7~61 | Permanent installation indoors, in cable ditches, pipes or underground.Be able to bear stronger outer mechanical force |

| 4, 6 | 4~14 | |||

| 10 | 4~10 | |||

| KYJVP2 | Copper Cores, XLPE Insulated, PVC Sheathed and Copper Taped ScreenedControl Cable | 0.75, 1.0, 1.5, 2.5 | 7~61 | Permanent installation indoors, in cable ditches or pipes where shielding is required |

| 4, 6 | 4~14 | |||

| 10 | 4~10 | |||

| KYJVR | Copper Cores, XLPE Insulated, PVC Sheathed, Flexible Control Cable | 0.5~2.5 | 4~61 | Installation indoors where flexibility and movability are required |

| KYJVRP | Copper Cores, XLPE Insulated, PVC Sheathed, and Braided ScreenFlexible Control Cable | 0.5, 0.75, 1.0 | 4~61 | Installation indoors where flexiblility, shielding and movability are required |

| 1.5, 2.5 | 4~48 |

Parameter

Component composition

Packaging: wooden barrel

Goods: finished product + wooden barrel packaging

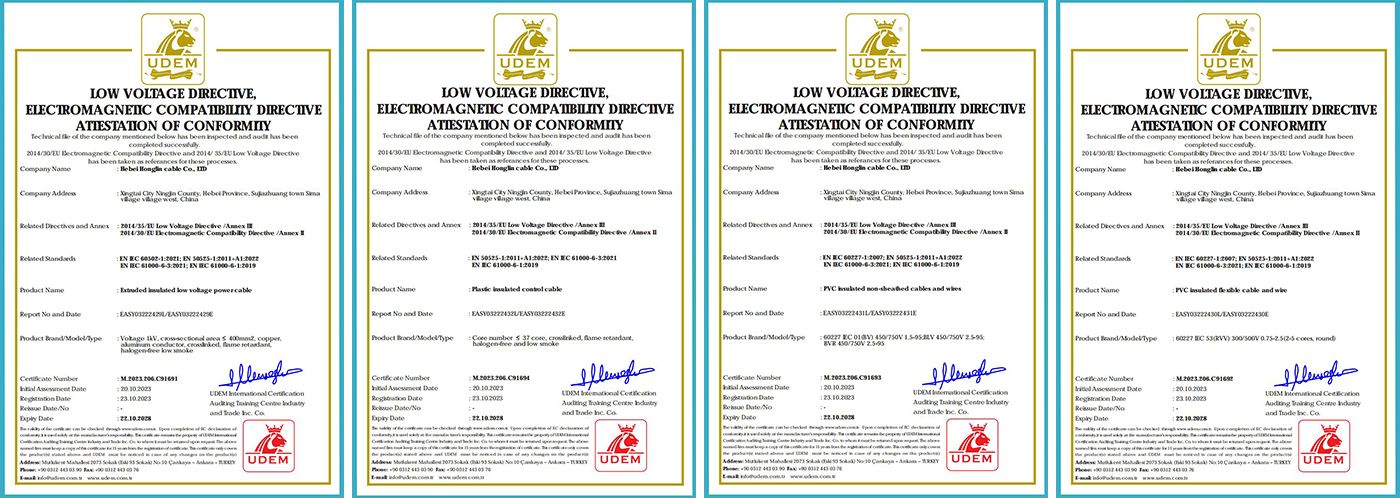

Certification

Manufacturing process

There are nine steps in the low-voltage power cable production process:stranding machine; extrud; cooling; diameter measurement; Bearing winch; Set meter counter; testing; Spark test; packing

Payment Method

T/T; L/C ; Western Union