Scan the QR code

Only one layer of insulation and only one conductor (usually copper wire).

The outer insulation material of the wire is made of rubber.

Rubber has good insulating properties and flexibility

Rated Voltage: 300/500V 450/750V 600/1000V

Introduction

Single-insulated single-core rubber-sheathed wire means that the outer insulation material of the wire is made of rubber, with only one layer of insulation and only one conductor (usually copper wire). Rubber has good insulating properties and flexibility, making rubber sheathed wires very suitable for some specific application scenarios.

Application

Single-core rubber sheathed wire is usually used in low-voltage household electrical installations, light electrical equipment and lighting circuits.

They are commonly found in household socket cords, light fixture cords, and extension cords.

However, due to the characteristics of single insulation, single-core rubber-sheathed wires cannot be directly exposed to moisture or high temperature to avoid damaging the insulation layer or causing safety issues such as electric shock.

Standards

IEC standards:

IEC 60245 is a standard for rubber sheathed cables and rubber sheathed conductors

IEC 60245-1 is about general requirements for rubber sheathed cables

IEC 60245-2 is the general requirements for rubber-sheathed conductors (single-core rubber-sheathed wires)

European standard:

EN 50525-2-21 is a standard for rubber sheathed conductors

Specification

Nominal Section-Area of Conductor(mm2) | Structure of Conductor | Nominal Thik-ness of Sheath (mm) | Overall Diameter | Max. Conductor Resistance at 20º C (Ω /km) | Approx. Weight (kg/km) | ||

Core no. /Dia. (no. /mm) | Min. | Max. | YH | YHF | |||

10 | 322/0.20 | 1.8 | 7.5 | 9.7 | 1.91 | 146 | 153.51 |

16 | 513/0.20 | 2.0 | 9.2 | 11.5 | 1.16 | 218.9 | 230.44 |

25 | 798/0.20 | 2.0 | 10.5 | 13.0 | 0.758 | 316.6 | 331.15 |

35 | 1121/0.20 | 2.0 | 11.5 | 14.5 | 0.536 | 426 | 439.87 |

50 | 1596/0.20 | 2.2 | 13.5 | 17.0 | 0.379 | 592.47 | 610.55 |

70 | 2214/0.20 | 2.4 | 15.0 | 19.5 | 0.268 | 790 | 817.52 |

95 | 2997/0.20 | 2.6 | 17.0 | 22.0 | 0.198 | 1066.17 | 1102.97 |

120 | 1702/0.30 | 2.8 | 19.0 | 24.0 | 0.161 | 1348.25 | 1392.55 |

150 | 2135/0.30 | 3.0 | 21.0 | 27.0 | 0.128 | 1648.5 | 1698.72 |

185 | 1443/0.40 | 3.2 | 22.0 | 29.0 | 0.106 | 1983.8 | 2020.74 |

Component composition

Packaging: wooden barrel

Goods: finished product + wooden barrel packaging

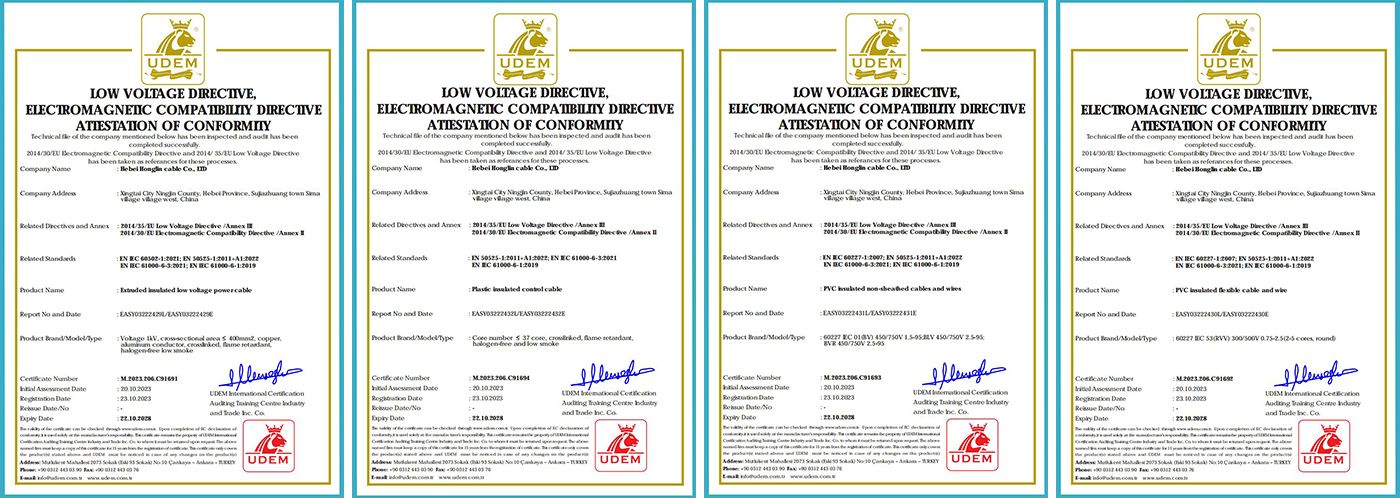

Certification

Manufacturing process

There are nine steps in the low-voltage power cable production process:stranding machine; extrud; cooling; diameter measurement; Bearing winch; Set meter counter; testing; Spark test; packing

Payment Method

T/T; L/C ; Western Union