Scan the QR code

Flexibility unmatched by other wires and cables

Good electrical insulation properties and chemical stability

Better physical and mechanical properties and wear resistance;

Oil resistance, flame retardant, cold resistance, heat resistance and other requirements

Introduction

Rubber sheathed cable is a soft and movable cable type made of multi-stranded thin copper wires as conductors, covered with rubber insulation and rubber sheath.

Generally speaking, it includes general rubber-sheathed flexible cables, welding machine cables, submersible motor cables, radio device cables and photography light source cables, etc. According to the mechanical external force on the cable, the product structure is divided into three categories: light, medium and heavy.

Application

Rubber sheathed cables are widely used in various electrical equipment, such as household appliances, electric machinery, electrical equipment and mobile power cords for appliances.

General lightweight rubber-sheathed cables: used in household appliances and small electric equipment, requiring softness, lightness, and good bending performance;

In addition to industrial use, medium-sized rubber sheathed cables are widely used in agricultural electrification;

Heavy-duty cables are used in applications such as port machinery, searchlights, and large-scale hydraulic drainage and irrigation stations. This type of product has good versatility, complete series specifications, good and stable performance

Specification

Type, Construction and Application of Products

| Type | Name | RatedVoltage(V) | Section Area(mm²) | Number of Cores | Application |

| 60245 IEC 53 YZ | Common Rubber SheathedFlexible Cable | 300/500 | 0.75~2.5 | 2,3,4,5 | Used for various movable electrical equipments and tools |

| 60245 IEC 57 YZW | Common ChloropreneRubber SheathedFlexible Cable | 300/500 | 0.75~2.5 | 2,3,4,5 | |

| 4~6 | 2,3,4,5 | ||||

| 60245 IEC 66 YC | Heavy Type RubberSheathed Flexible Cablefor Outdoor Using | 450/750 | 1.5~400 | 1 | Used for various movable electrical equipment and be able to support stronger external mechanical force |

| 1.0~25 | 2 | ||||

| 1.0~95 | 3 | ||||

| 1.0~150 | 4 | ||||

| 1.0~25 | 5 | ||||

| YC | Heavy Type RubberSheathed Flexible Cable | 450/750 | 1.5~400 | 1 | |

| 1.5~95 | 2 | ||||

| 1.5~150 | 3,4 | ||||

| 1.5~25 | 5 | ||||

| 2.5~150 | 4(three and half cores) |

component composition

Packaging: wooden barrel

Goods: finished product + wooden barrel packaging

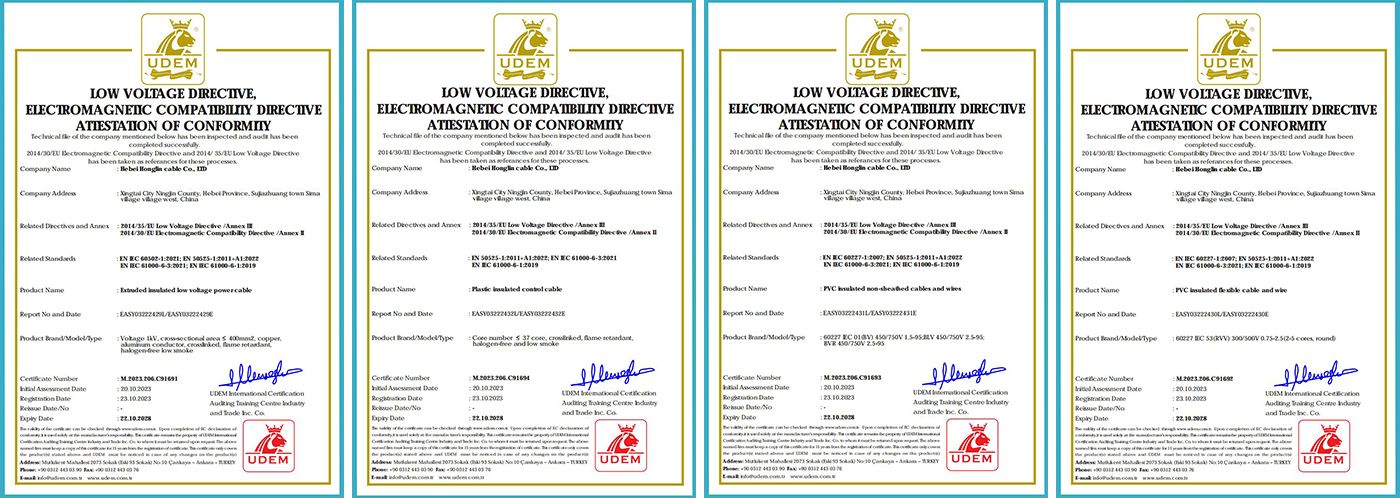

Certification

Manufacturing process

There are nine steps in the low-voltage power cable production process:stranding machine; extrud; cooling; diameter measurement; Bearing winch; Set meter counter; testing; Spark test; packing

Payment Method

T/T; L/C ; Western Union