Scan the QR code

Alloy conductor

Lightweight、Low cost

Good electrical conductivity

Good elasticity and flexibility

Good insulation performance

Corrosion resistance

Rubber-sheathed wire is a type of wire that has an outer protective layer of rubber or rubber-like material to provide insulation and protect the wire. Rubber-sheathed wire is usually composed of a conductor, an insulating layer, and an outer rubber sheath.

The conductor part can be copper wire, aluminum wire, or aluminum alloy wire, which is used to transmit current or signals. Copper wire generally has good conductivity and is therefore widely used in many applications.

The outer rubber sheath is a protective layer covering the insulation layer to provide mechanical protection and durability. The rubber sheath can resist physical damage, chemical corrosion, and environmental factors, while also providing softness and elasticity, making the wire easier to bend and install.

Rubber-sheathed wire is commonly used in a variety of electrical applications, including low-voltage power transmission, lighting systems, motor connections, instrumentation, etc. The choice of rubber-sheathed wire depends on the needs of the specific application, such as current load, operating environment, temperature range, and durability requirements.

Standards

IEC standards:

IEC 60245 is a standard for rubber sheathed cables and rubber sheathed conductors

IEC 60245-1 is about general requirements for rubber sheathed cables

IEC 60245-2 is the general requirements for rubber-sheathed conductors (single-core rubber-sheathed wires)

European standard:

EN 50525-2-21 is a standard for rubber sheathed conductors

Specification

Nominal Section-Area of Conductor(mm2) | Structure of Conductor | Nominal Thik-ness of Sheath (mm) | Overall Diameter | Max. Conductor Resistance at 20º C (Ω /km) | Approx. Weight (kg/km) | ||

Core no. /Dia. (no. /mm) | Min. | Max. | YH | YHF | |||

10 | 322/0.20 | 1.8 | 7.5 | 9.7 | 1.91 | 146 | 153.51 |

16 | 513/0.20 | 2.0 | 9.2 | 11.5 | 1.16 | 218.9 | 230.44 |

25 | 798/0.20 | 2.0 | 10.5 | 13.0 | 0.758 | 316.6 | 331.15 |

35 | 1121/0.20 | 2.0 | 11.5 | 14.5 | 0.536 | 426 | 439.87 |

50 | 1596/0.20 | 2.2 | 13.5 | 17.0 | 0.379 | 592.47 | 610.55 |

70 | 2214/0.20 | 2.4 | 15.0 | 19.5 | 0.268 | 790 | 817.52 |

95 | 2997/0.20 | 2.6 | 17.0 | 22.0 | 0.198 | 1066.17 | 1102.97 |

120 | 1702/0.30 | 2.8 | 19.0 | 24.0 | 0.161 | 1348.25 | 1392.55 |

150 | 2135/0.30 | 3.0 | 21.0 | 27.0 | 0.128 | 1648.5 | 1698.72 |

185 | 1443/0.40 | 3.2 | 22.0 | 29.0 | 0.106 | 1983.8 | 2020.74 |

Component composition

Packaging: wooden barrel

Goods: finished product + wooden barrel packaging

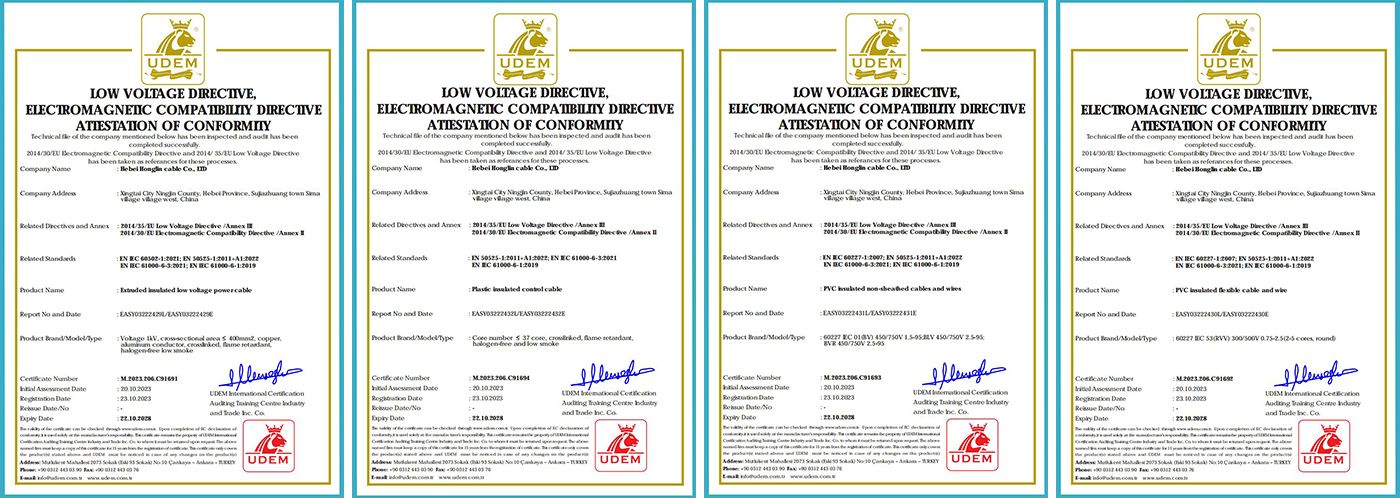

Certification

Manufacturing process

There are nine steps in the low-voltage power cable production process:stranding machine; extrud; cooling; diameter measurement; Bearing winch; Set meter counter; testing; Spark test; packing

Payment Method

T/T; L/C ; Western Union