Scan the QR code

It has rubber or rubber sheath insulation and a steel core clad on the inside.

This design makes the rubber sheathed wire have higher mechanical strength and wear resistance.

Often used where extra protection and support is needed

Introduction

Rubber jacketed wire with a steel core is a type of wire that has a steel core wrapped within a rubber or rubber jacket insulation. This design gives the rubber sheathed wire higher mechanical strength and durability.

Rubber jacketed wire with a steel wire core is common in some special industrial, construction and stage equipment applications. However, specific specifications and uses may vary across different industries and applications, so relevant standards and recommendations should be consulted when selecting and using to ensure safety and suitability.

Application

Suspension wire: Due to the strength of the steel wire core, rubber-covered wire with a steel wire core can withstand greater tension and mechanical stress. Can be used to hang wires, allowing them to span longer distances without being prone to sagging or damage. They are often used where extra strength support is required, such as lifting cables, lifting equipment, etc.

Hanging Lighting Fixtures: For larger or heavy-duty decorative fixtures, rubber-covered wire with a steel core can add strength and stability to ensure the fixture stays where you want it.

Power transmission in industrial environments: In some industrial environments that require frequent movement or exposure to harsh conditions, rubber-sheathed wires with steel cores can provide better protection and durability.

Standards

IEC standards: such as IEC 60245 series

European standards: EN 50525 series

Chinese standards: SAC has released a series of national standards for rubber sheathed wires, such as GB/T 5013 (rubber insulated flexible cables) and GB/T 5023 (rubber sheathed wires)

Specification

| Conductor | Class 5 flexible copper conductor |

| Insulation | Rubber (EPR) |

| Sheath | Rubber (CR) |

| Voltage Rating | 450/750V |

| Temperature Rating | -25°C to +60°C |

| Core identification color | VDE 0293 (hd308) |

| Sheath Colour | Black |

Component composition

Packaging: wooden barrel

Goods: finished product + wooden barrel packaging

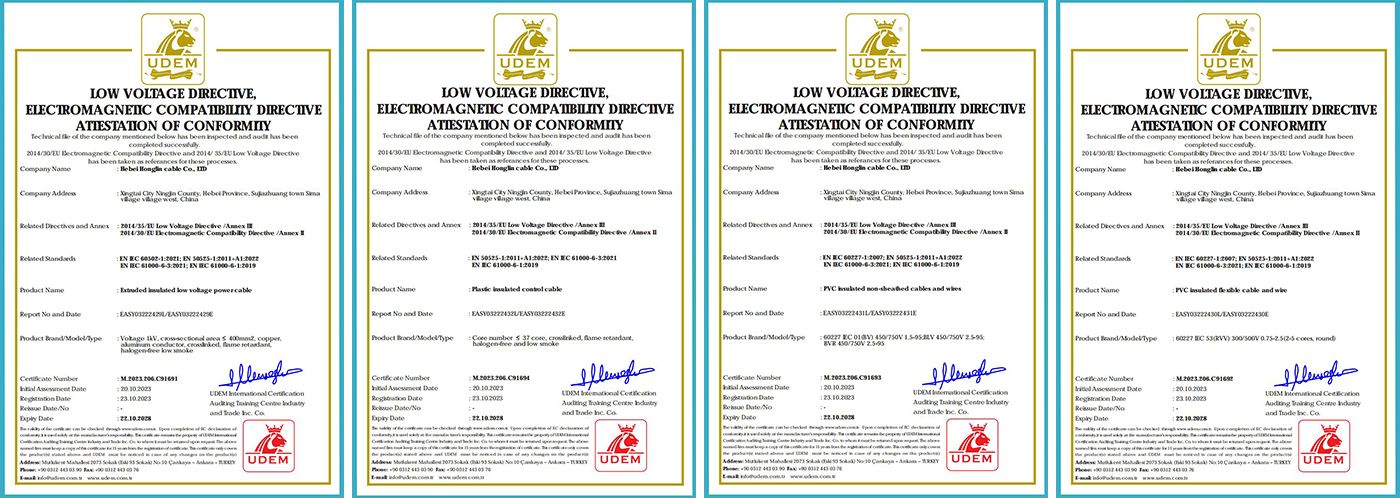

Certification

Manufacturing process

There are nine steps in the low-voltage power cable production process:stranding machine; extrud; cooling; diameter measurement; Bearing winch; Set meter counter; testing; Spark test; packing

Payment Method

T/T; L/C ; Western Union