Scan the QR code

double insulation single core

Flexibility unmatched by other wires and cables

Good electrical insulation properties and chemical stability

Better physical and mechanical properties and wear resistance;

Oil resistance, flame retardant, cold resistance, heat resistance and other requirements

Introduction

Rubber sheathed cable is a soft and movable cable type made of multi-stranded thin copper wires as conductors, covered with rubber insulation and rubber sheath.

Generally speaking, it includes general rubber-sheathed flexible cables, welding machine cables, submersible motor cables, radio device cables and photography light source cables, etc. According to the mechanical external force on the cable, the product structure is divided into three categories: light, medium and heavy.

Application

Metal processing and manufacturing: It is commonly used for welding metal structures, welding metal pipes, repairing machinery and equipment, etc. This includes areas such as automobile manufacturing, shipbuilding, bridge construction, construction industry, machine manufacturing, etc.

Electronics and electrical appliances industry: It is used for soldering electronic components, circuit boards, wires and cables, etc.

Construction and building maintenance: including welded steel structures, welded metal doors and windows, roof and staircase repairs, and more.

Car repair and modification: It is used for body repair, chassis repair, welding exhaust system and modified vehicles, etc.

Metal Art and Handcrafting: It can be used to create metal sculptures, iron art, handmade jewelry, etc.

AWS A5.18/A5.18M: A standard developed by the American Welding Society that specifies specifications and requirements for welding wire and covers a variety of welding applications.

ISO 14341: A standard developed by the International Organization for Standardization that specifies the classification and technical requirements for welding wires (including welding wires) used for shielded gas welding.

GB/T 8110: A standard formulated by the Standardization Administration of China that stipulates the classification, marking and technical requirements for welding wires, including welding wires.

Specification

Size (mm²) | Conductor Structure (No./mm) | Sheath Thickness | Max Overall Diameter | Approx. Weight (Kg/Km) | Max D.C Resistance (20℃) | Permissible Current Rating(A) |

10 | 322/0.2 | 1.8 | 9.7 | 133 | 1.91 | 75 |

16 | 513/0.2 | 2 | 11.5 | 216 | 1.16 | 105 |

25 | 798/0.2 | 2 | 13 | 300 | 0.758 | 135 |

35 | 1121/0.2 | 2 | 14.5 | 406 | 0.536 | 170 |

50 | 1596/0.2 | 2.2 | 17 | 568 | 0.379 | 215 |

70 | 2220/0.2 | 2.4 | 19.5 | 780 | 0.268 | 265 |

95 | 2997/0.2 | 2.6 | 22 | 1037 | 0.198 | 325 |

120 | 1702/0.3 | 2.8 | 24 | 1314 | 0.161 | 380 |

150 | 2146/0.3 | 3 | 27 | 1644 | 0.129 | 435 |

185 | 1443/0.3 | 3.2 | 29 | 1957 | 0.106 | 496 |

Component composition

Packaging: wooden barrel

Goods: finished product + wooden barrel packaging

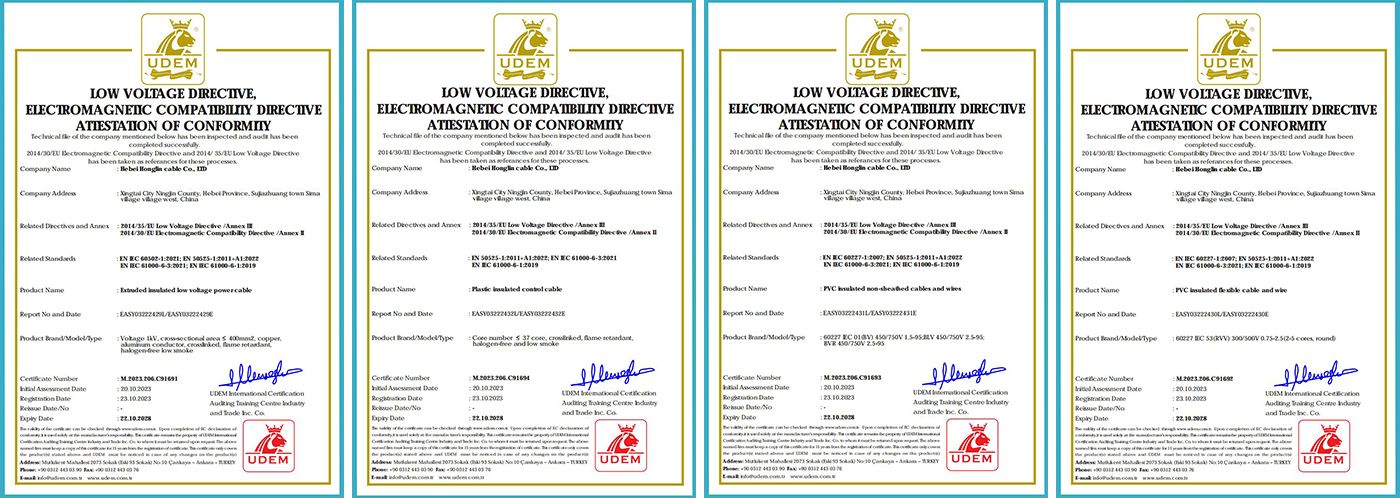

Certification

Manufacturing process

There are nine steps in the low-voltage power cable production process:stranding machine; extrud; cooling; diameter measurement; Bearing winch; Set meter counter; testing; Spark test; packing

Payment Method

T/T; L/C ; Western Union