Scan the QR code

Oil, solvent and corrosion resistant / Vibration and shock resistance / Fire performance / High degree of sealing

Conductor material: copper conductor

Insulation materials: Common insulation materials include polyvinyl chloride (PVC), cross-linked polyethylene (XLPE), rubber, etc.

Sheath material: polyvinyl chloride (PVC), cross-linked polyethylene (XLPE), acrylonitrile-butadiene rubber (NBR), etc.

Flame retardant materials: low smoke halogen-free (LSZH) materials, flame retardant polyolefin (FR-PE), etc.

Introduction

Marine cables are cables specially used for power and signal transmission within ships. Marine cables play important functions in ships such as power supply, equipment connection and signal transmission. They are widely used in ships' electrical systems, communication systems and automation systems.

Application

Marine cables are widely used in various electrical systems, communication systems and automation systems of ships. The following are the main application scenarios of marine cables:

Power systems: They connect generators, main electrical panels, motors, transformers and other power equipment to ensure the supply and distribution of power to the ship.

Lighting system: Connect lamps, lighting switches and control devices to provide lighting inside and outside the ship.

Control system: Connect sensors, actuators, controllers and monitoring equipment to monitor and control various systems and equipment of the ship.

Navigation system: Marine cables are used in ship navigation systems, including radar, GPS, compass and navigation instruments.

Fire prevention system: Connect fire alarms, fire extinguishing devices and controllers to monitor, alarm and control ship fires.

Specification

Component composition

Packaging: wooden barrel

Goods: finished product + wooden barrel packaging

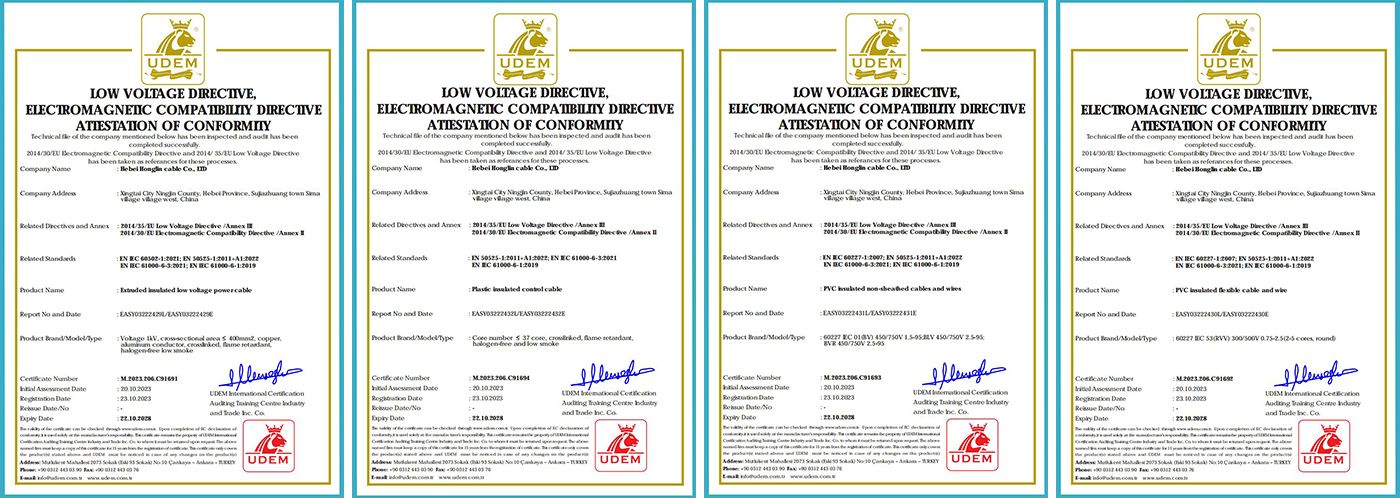

Certification

Manufacturing process

There are nine steps in the low-voltage power cable production process:stranding machine; extrud; cooling; diameter measurement; Bearing winch; Set meter counter; testing; Spark test; packing

Payment Method

T/T; L/C ; Western Union