Scan the QR code

It has the characteristics of wear resistance, corrosion resistance, high temperature resistance and tensile strength resistance.

Mining cables need to be waterproof to prevent moisture from entering the cable and causing short circuits or other failures.

Mining cables use shielding layers or other anti-interference technologies to reduce the impact of external interference on signal transmission.

Introduction

Mining cables refer to wire and cable products for ground equipment and underground equipment used in the coal mining industry. These include cables for shearers, transporters, communications, lighting and signaling equipment, as well as electric drill cables, cap lamp wires and power cables for underground mobile substations.

Application

1.It is used in coal mines to transport electrical energy, supply lighting equipment, transportation equipment, ventilation systems and drainage pumps and other equipment.

2.t is used in metal mines to transmit electricity, supply control systems, drive mechanical equipment and robots, etc.

3.Used in tunneling projects to supply power and control systems.

4.Mining cables are used to connect and power various mechanical equipment in mines, such as mining machines, crushers, transportation equipment, lifting equipment, etc.

Standards

IEC 60287、IEC 60502、IEC 60811

GB/T 12706、GB/T 9330、GB/T 19666

Specification

Size(mm) | Insulation Thickness (mm) | Sheath Thickness(mm) | Outer Diameter (mm) |

3*16 | 4.0 | 5.5 | 48.0-55.0 |

3*25 | 4.0 | 5.5 | 51.0-58.0 |

3*35 | 4.0 | 5.5 | 54.0-61.0 |

3*50 | 4.0 | 5.5 | 58.0-66.0 |

3*70 | 4.0 | 6.0 | 64.0-72.0 |

3*120 | 4.0 | 6.0 | 71.0-80.0 |

Customize | |||

Component composition

Packaging: wooden barrel

Goods: finished product + wooden barrel packaging

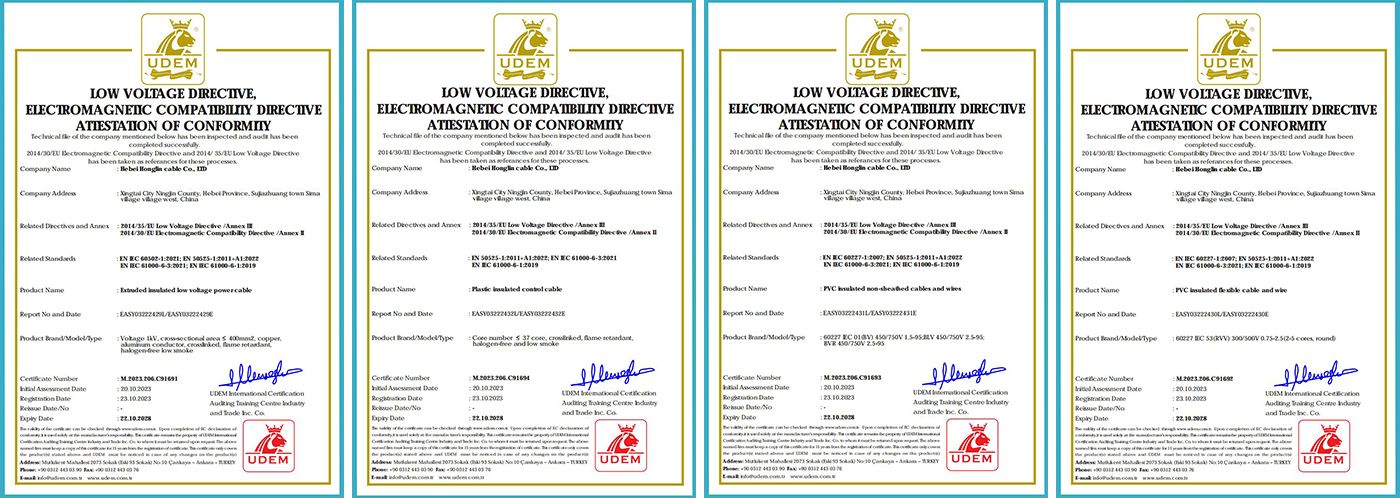

Certification

Manufacturing process

There are nine steps in the low-voltage power cable production process:stranding machine; extrud; cooling; diameter measurement; Bearing winch; Set meter counter; testing; Spark test; packing

Payment Method

T/T; L/C ; Western Union