Scan the QR code

Conductor:Tinned Copper

Flexible, good bending performance, certain fire resistance

Has excellent electrical insulation properties and good anti-electromagnetic interference capabilities

Has excellent electrical insulation properties

The electrical energy generated is usually direct current, and the current is relatively large

Introduction

The 0.6/1KV solar cable is a tinned copper conductor, XLPO insulation, and LSZH sheath, which is designed for connecting photovoltaic system components inside and outside of buildings and equipment with high mechanical requirements and extreme weather conditions. It has the characteristics of UV resistance, wears resistance, and aging resistance, and the service life is more than 25 years.

Application

Large photovoltaic power generation

Photovoltaic industrial building

City street light Large photovoltaic power generation

Large photovoltaic power generation in public place

Rueal building Large photovoltaic power generation

photovoltaic installation drawing

Standard

EN 50618、TUV 2PfG 1169

Specification

Product name | Solar cable |

Place of Origin | China,Hebei |

Brand Name | Honglin |

Conductor | Tinned copper |

Insulation | XLPO/XLPE |

Core | 1-2 Core |

Working temperature | -40℃-125℃ |

Standard | IEC60228 |

Rated Voltage | 450/750V |

Size | Customization |

Package | 100M/Roll,customize |

single core solar pv power cable

Cross section (mm2) | Conductor Construction | Outer (mm) | Resistance Max. | Current Carring Capacity |

1*1.5 | 30/0.25 | 4.90 | 13.30 | 30 |

1*2.5 | 50/0.25 | 5.45 | 7.89 | 41 |

1*4 | 56/0.3 | 6.10 | 4.75 | 50 |

1*6 | 84/0.3 | 7.20 | 3.39 | 70 |

1*10 | 142/0.3 | 9.00 | 1.95 | 98 |

1*16 | 228/0.3 | 10.20 | 1.24 | 132 |

1*25 | 361/0.3 | 12.00 | 0.795 | 176 |

1*35 | 525/0.3 | 13.8 | 0.565 | 218 |

1*50 | 720/0.3 | 14.8 | 0.393 | 280 |

1*70 | 988/0.3 | 16.9 | 0.277 | 350 |

1*95 | 1349/0.3 | 18.7 | 0.21 | 410 |

1*120 | 1691/0.3 | 20.7 | 0.164 | 480 |

Twin/Dual core solar pv power cable

Cross section (mm2) | Conductor Construction | Outer (mm) | Resistance Max. | Current Carring Capacity |

2 x 1.5 | 30/0.25 | 8.3 ± 0.2 | 13.30 | 30 |

2 x 2.5 | 50/0.25 | 9.2 ± 0.2 | 7.98 | 41 |

2 x 4 | 56/0.3 | 12.0 ± 0.2 | 4.75 | 50 |

2 x 6 | 84/0.3 | 13.5 ± 0.2 | 3.39 | 70 |

2 x 10 | 142/0.3 | 17.6 ± 0.2 | 1.95 | 98 |

2 x 16 | 228/0.3 | 19.8 ± 0.2 | 1.24 | 132 |

Component composition

Packaging: wooden barrel

Goods: finished product + wooden barrel packaging

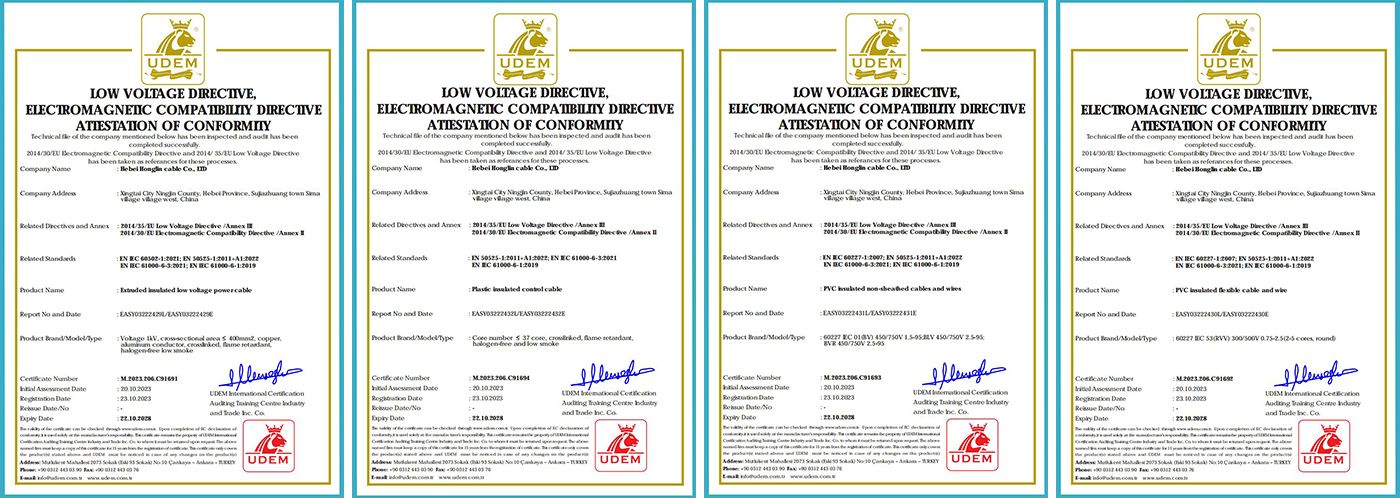

Certification

Manufacturing process

There are nine steps in the low-voltage power cable production process:stranding machine; extrud; cooling; diameter measurement; Bearing winch; Set meter counter; testing; Spark test; packing

Payment Method

T/T; L/C ; Western Union