Scan the QR code

Conductor: Aluminum alloy,Tinned copper

Insulation: PVC、XLPE

Voltage: 3001500V or 4501750V or 60011000V

Introduction

These cables are designed for connecting photovoltaic system components inside and outside of buildings and equipment with high mechanical requirements and extreme weather conditions.

Application

Photovoltaic cables are used to connect electrical energy between solar panels and inverters.

Photovoltaic cables can be used to transmit electricity generated by solar power systems into the grid for use by other users.

Photovoltaic cables can also be used for wiring within solar power systems.

Photovoltaic cables are also used to connect monitoring and control equipment in solar power systems, such as data collectors, inverter controllers and monitoring systems.

Standards

IEC 60227: This standard specifies the requirements for power cables for general use, including photovoltaic cables.

IEC 60245: This standard specifies the requirements for rubber and rubber-insulated cables, including some used in photovoltaic applications.

EN 50618: This is a European standard that specifies the requirements for DC low voltage cables for photovoltaic systems.

Specification

NO. OF CORES ×NOMINAL CROSS SECTION | NOMINAL CONDUCTOR DIAMETER | NOMINAL INSULATION THICKNESS | NOMINAL SHEATH | NOMINAL OVERALL DIAMATER |

NO. ×MM² | MM | MM | MM | MM |

1*1.5 | 1.58 | 1.14 | 0.82 | 5.4 |

1*2.5 | 2.04 | 1.14 | 0.82 | 5.8 |

1*4 | 2.59 | 1.14 | 0.82 | 6.4 |

1*6 | 3.17 | 1.14 | 0.82 | 7.0 |

1*10 | 4.07 | 1.52 | 0.82 | 8.6 |

1*16 | 5.22 | 1.52 | 0.82 | 9.8 |

1*25 | 6.51 | 1.52 | 0.82 | 11.1 |

Component composition

Packaging: wooden barrel

Goods: finished product + wooden barrel packaging

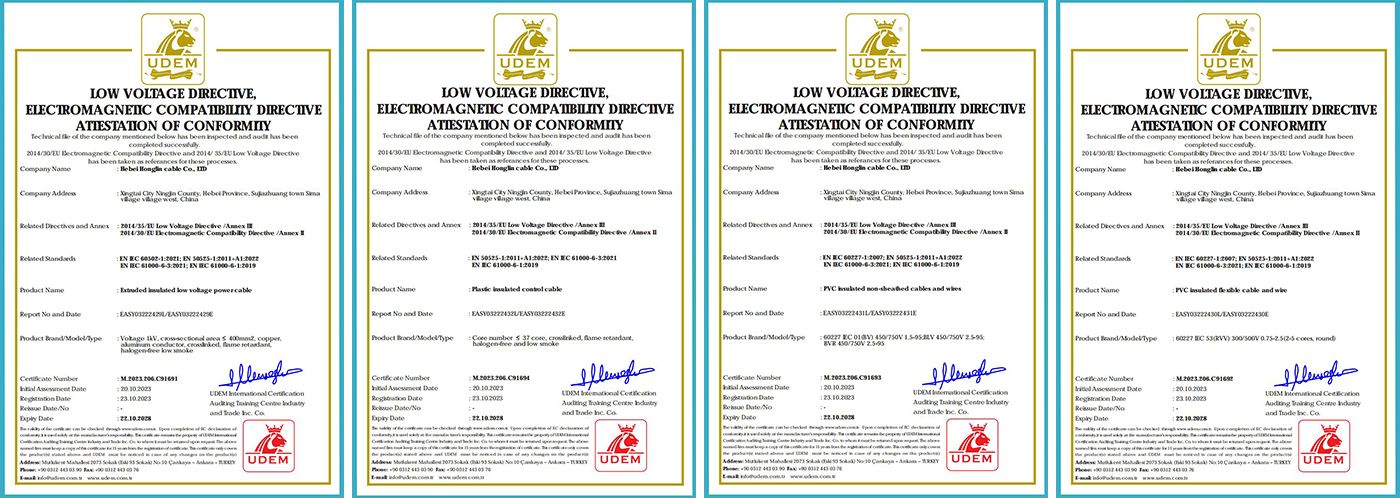

Certification

Manufacturing process

There are nine steps in the low-voltage power cable production process:stranding machine; extrud; cooling; diameter measurement; Bearing winch; Set meter counter; testing; Spark test; packing

Payment Method

T/T; L/C ; Western Union