Scan the QR code

BV wires are designed and manufactured to strict safety standards. It is insulated with high-quality PVC (polyvinyl chloride) material, which has excellent electrical insulation and can prevent electric shock and short circuit.

Durability: PVC insulation is resistant to abrasion, moisture, chemicals and UV radiation, ensuring the wire can withstand a variety of environmental conditions without degrading.

Easy to install: Wires can be easily bent, routed and secured in place, simplifying the installation process and reducing labor time and costs.

Cost-effective: BV wire is generally less expensive than other types of wire, making it a cost-effective choice for electrical installations.

Introduction

Single-core non-sheathed cables with rigid conductor for general purposes.

Code design: 60227 IEC 01(International), BV 450/750V(China), H07V-U(VDE)

Application

Used as fixed wiring cable of rated voltage 300/500V.

In dry rooms, apparatus switch and distribution boards, for fixed installation in conduits, over and under plaster and on insulation supports over plaster. Direct laying in plaster is not permitted.

Specification

| Nominal Section(mm) | Stranding/Single Wire Diameter(mm) | Maximum Outer Diameter(mm²) | Reference Weight(kg/km) | Conductor Resistance at 20℃(Ω/km) | ||

| Copper | Aluminum | Aluminum | Copper | |||

| 1.5(A) | 1/1.38 | 3.3 | 20.3 | 12.1 | ||

| 1.5(B) | 7/0.52 | 3.5 | 21.6 | 12.1 | ||

| 2.5(A) | 1/1.78 | 3.9 | 31.6 | 17 | 11.8 | 7.41 |

| 2.5(B) | 7.0.68 | 4.2 | 34.8 | 7.41 | ||

| 4(A) | 1/2.55 | 4.4 | 47.1 | 22 | 7.39 | 4.61 |

| 4(B) | 7/0.85 | 4.8 | 50.3 | |||

| 6(A) | 7/0.85 | 4.8 | 50.3 | 29 | 4.91 | 3.08 |

| 6(B) | 7/1.04 | 5.4 | 71.2 | 3.08 | ||

| 10 | 7/1.35 | 7.0 | 11.9 | 62 | 3.08 | 1.83 |

| 16 | 1/1.70 | 8.0 | 179 | 78 | 1.91 | 1.15 |

| 25 | 27/2.04 | 10.0 | 281 | 118 | 1.20 | 0.727 |

| 35 | 27/2.52 | 11.5 | 381 | 156 | 1.868 | 0.524 |

| 50 | 19/1.78 | 13.0 | 521 | 215 | 0.641 | 0.387 |

| 70 | 19/2.14 | 15.0 | 734 | 282 | 0.443 | 0.268 |

| 95 | 19/2.52 | 17.5 | 962 | 385 | 0.320 | 0.193 |

| 120 | 37/2.03 | 19.0 | 1180 | 431 | 0.253 | 0.153 |

Component composition

Packaging: wooden barrel

Goods: finished product + wooden barrel packaging

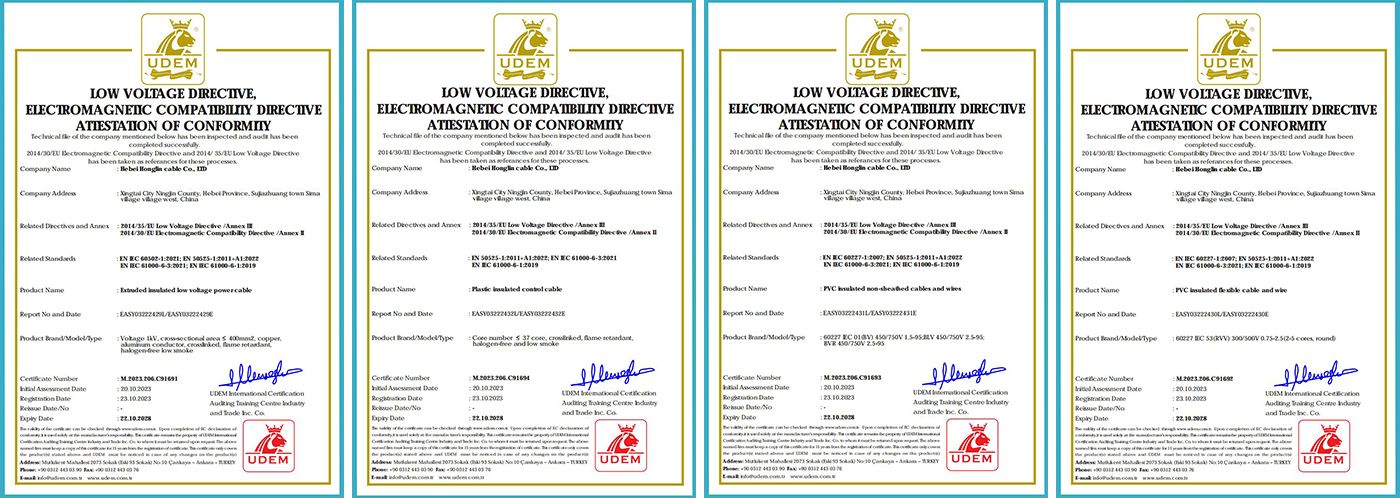

Certification

Manufacturing process

There are nine steps in the low-voltage power cable production process:stranding machine; extrud; cooling; diameter measurement; Bearing winch; Set meter counter; testing; Spark test; packing

Payment Method

T/T; L/C ; Western Union