Multi-stranded soft copper conductors

Composed of small copper wire

Suitable for situations that require frequent movement or bending

PVC Insulation

Introduction

RVV is the abbreviation of "Copper Core PVC Insulated PVC Sheathed Cable" (Copper Core PVC Insulated PVC Sheathed Cable).

RVV is a common type of wire and cable commonly used for indoor electrical wiring and low-voltage power transmission

RVV wire and cable are multi-core cables, usually composed of 2 or more copper core conductors. Each conductor is insulated with PVC insulation material.

The conductors of RVV wires and cables are made of polyvinyl chloride (PVC) insulation material. PVC insulation provides good electrical insulation properties, protecting conductors from electrical interference.

Application

RVV cables are mainly used in flexible places such as medium and light mobile appliances, instrumentation, household appliances, and power lighting. They can transmit control signals and power signals. They are also suitable for laying in bridges and hoses.

Specification

| Nominal Cross Sectional Areamm² | Insulation Thicknessmm | Sheath Thicknessmm | Average Overall Diameter | Min.Insulation Resistance at 70℃MΩ•Km | Approx.Weightkg/km | |

| Min. | Max. | |||||

| 2×0.75 | 0.6 | 0.8 | 5.7 | 7.2 | 0.011 | 54.1 |

| 2×1 | 0.6 | 0.8 | 5.9 | 7.5 | 0.01 | 2.3 |

| 2×1.5 | 0.7 | 0.8 | 6.8 | 8.6 | 0.01 | 82.1 |

| 2×2.5 | 0.8 | 1 | 8.4 | 10.6 | 0.009 | 126.3 |

| 3×0.75 | 0.6 | 0.8 | 6 | 7.6 | 0.011 | 64.5 |

| 3×1 | 0.6 | 0.8 | 6.3 | 8 | 0.01 | 75.1 |

| 3×1.5 | 0.7 | 0.9 | 7.4 | 9.4 | 0.01 | 103.4 |

| 3×2.5 | 0.8 | 1.1 | 9.2 | 11.4 | 0.009 | 158.8 |

| 4×0.75 | 0.6 | 0.8 | 6.6 | 8.3 | 0.011 | 79 |

| 4×1 | 0.6 | 0.9 | 7.1 | 9 | 0.01 | 96 |

| 4×1.5 | 0.7 | 1 | 8.4 | 10.5 | 0.01 | 131.9 |

| 4×2.5 | 0.8 | 1.1 | 10.1 | 12.5 | 0.009 | 196.7 |

| 5×0.75 | 0.6 | 0.9 | 7.4 | 9.3 | 0.011 | 99 |

| 5×1 | 0.6 | 0.9 | 7.8 | 9.8 | 0.01 | 116 |

| 5×1.5 | 0.7 | 1.1 | 9.3 | 11.6 | 0.01 | 164.1 |

| 5×2.5 | 0.8 | 1.2 | 11.2 | 13.9 | 0.009 | 244.4 |

| Nominal CrossSection Areamm² | Insulation Thicknessmm | Sheath Thicknessmm | Approx.Overall Diameter of Cablemm | Approx.Weightkg/km |

| 2×4 | 0.8 | 1.1 | 6.3×10.4 | 141.2 |

| 2×6 | 0.8 | 1.1 | 6.9×11.6 | 187.2 |

| 2×10 | 1.0 | 1.2 | 8.2×14.0 | 294.0 |

| 2×16 | 1.0 | 1.3 | 9.5×16.4 | 426.7 |

| 2×1.5 | 0.6 | 0.9 | 4.6×7.3 | 64.5 |

| 2×2.5 | 0.7 | 1.0 | 5.4×8.8 | 95.4 |

| 2×2.5+1×2.5 | 0.8 | 1.1 | 6.3×13.8 | 170.1 |

| 2×6+1×2.5 | 0.8 | 1.1 | 6.9×12.8 | 213.1 |

| 2×1.5+1×1.5 | 0.6 | 0.9 | 4.6×10.1 | 93.9 |

| 2×2.5+1×2.5 | 0.7 | 1.0 | 5.4×12.1 | 0.7139.7 |

Component composition

Packaging: wooden barrel

Goods: finished product + wooden barrel packaging

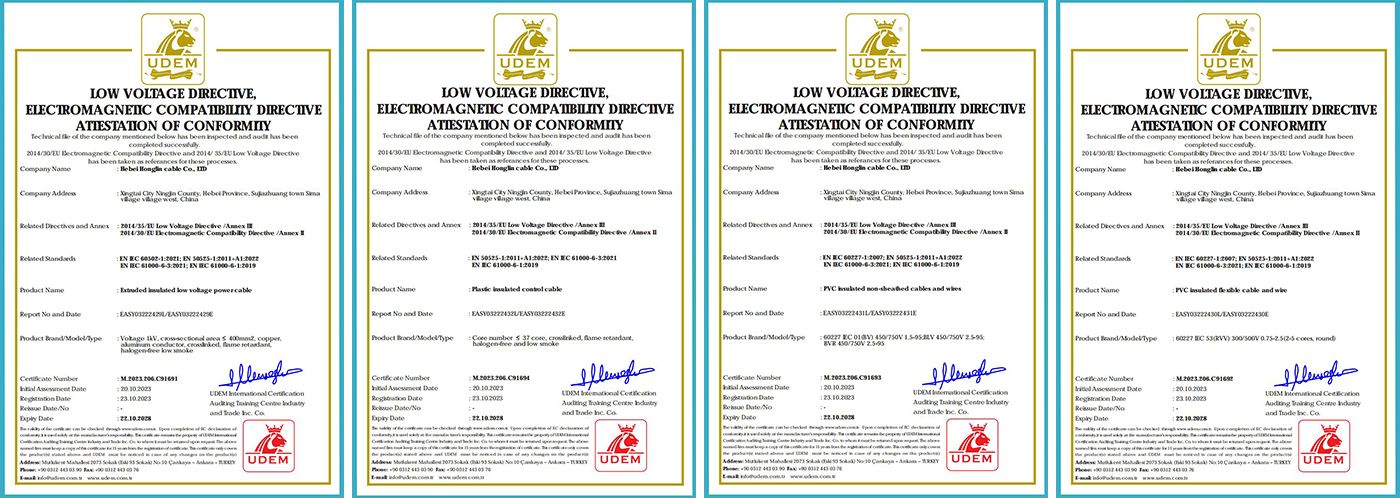

Certification

Manufacturing process

There are nine steps in the low-voltage power cable production process:stranding machine; extrud; cooling; diameter measurement; Bearing winch; Set meter counter; testing; Spark test; packing

Payment Method

T/T; L/C ; Western Union